- Stock: In Stock

- Article #: vsc-001

Available Options

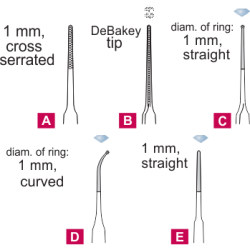

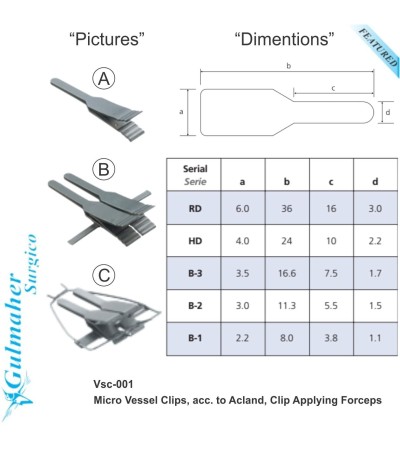

While picking the correct size of vessel clamp for your work, pressure & weight is a critical thought. Clamp weight is dictated by the end power of the clip (in grams), isolated by the region of the vessel divider that is packed between the jaws (in square millimeters). Hence, the littler the zone, the higher the weight is, conversely corresponding to the vessel estimate. Each size of the cinch has its very own unique and deliberately aligned shutting power. Each clip measure is intended for a particular scope of vessel distances across.

Vessel Leakage:

Indeed, even on the biggest, suggested measurement vessel, each size of the brace will withstand pulse inside the vessel up to 200 mm Hg, without spillage. In spite of the extensive variety of shutting powers, the weight applied by each cinch, huge or little, stays predictable all through the arrangement. Each size of cinch applies a weight of 5gm/mm2 when utilized on the biggest vessel in its range, and 15gm/mm2 at the point when utilized on the littlest vessel. Indeed, even at the higher range, 's clinical smaller scale cinches have the gentlest working weight of any little vessel clip accessible. The table abridges the connection between clip measure, suggested vessel distance across and cinch weight. "Vessel measurement" alludes to the outer distance across of the vessel in its characteristic condition of full widening. There is a half cover in the prescribed vessel breadth extent, between each clip measure and the following bigger or littler size. In this manner, for each vessel measurement, except for those at the outrageous closures of the range, there will dependably be two reasonable clips. At whatever point a decision emerges, the littler clip ought to be chosen to guarantee a gentler, less compelled treatment of the vessel.

- Sterilization: Surgical instruments may be steam autoclaved at a temperature of 121°C (250°F) for 30 minutes or flash autoclaved at a temperature of 127° to 132°C (260° to 270°F) for 10 minutes.

- Recommended Sterilization Parameters: PRE-VAC Unwrapped Goods Cycle 5 minutes at 132° C/270° F. Dry Time: none recommended.

Wrapped Goods Cycle 5 minutes @ 132° C/270° F Dry Time: 5‐20 minutes*

- Recommended Gravity. Unwrapped Goods Cycle 10 minutes @ 132° C/270° F Dry time: none recommended. Wrapped Goods Cycle 30 Minutes @ 132° C/270° F Dry Time: per facility recommendation. Wrapped Goods Cycle 60 Minutes @ 132° C/270° F Dry Time: per facility recommendation. *Depending on Hospital Protocol* Warning: Flash sterilization is not the recommended sterilization method. All surgical instruments and parts should be steam autoclaved when time permits. However, flash sterilization may be used when there is an immediate need for an instrument, injector, or accessory and there is no other alternative.

- Aeration: As required to return to room temperature or to start the next cycle.

- Contraindication: Hospital policy and procedure(s) take precedence over this protocol. Failure to use approved cleaning and sterilization procedures may void the warranty.

- Cleaning Instructions: Cleaning: All instruments must be cleaned to remove contaminated substances before sterilization. After each use, perform an initial cleaning within the sterile field by wiping the tool or instrument free of blood and body fluids. Then clean the instrument thoroughly with a mild soapy solution. Do not use alkaline-based cleaners. Complete preparation for sterilization by hospital procedure using an approved cleaning agent. Do not run any type of abrasive materials or steel brushes through the lumen of the tool. The abrasive material can score the inside of the tool, rendering them inefficient. After flushing, the instrument needs to be well-rinsed with warm to hot water. Visually inspect each instrument to ensure all fatty deposits are removed. All instruments should be cleaned and rinsed with mild, non-abrasive, grease-removing cleaners before they are sterilized. Gulmaher Instruments recommends that during the cleaning and rinsing procedures, all instruments should be inspected. Ultrasonic cleaning after manual cleaning is recommended.

Refund / Return Goods Policy

- Item must be in unused condition and the original packaging Or unopened. Sterilized, taped, modified, or abused items cannot be returned or refunded for credit.

- The customer is responsible for returning the item(s) to Gulmaher. Gumaher will issue merchandise return labels if the return is a result of Gulmaher's mishandling (shipping error, etc.).