- Stock: In Stock

- Article #: 1614-42

Available Options

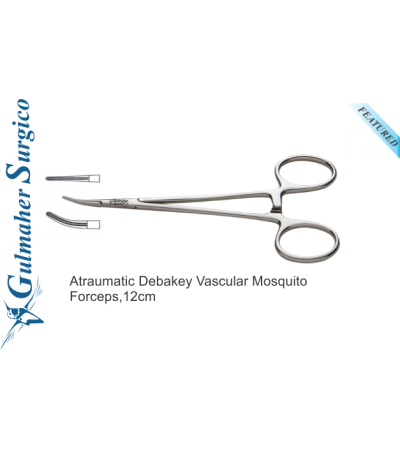

DeBakey Halsted Mosquito Forceps are utilized in different methods as a hemostat for narrow veins. The tightened finger ring handle gives a safe, locking hold to stop bloodstream. They are not suitable for use with extensive vessels or courses. A toothed variety is accessible for getting a handle on delicate tissue in skin uniting, biopsies, or ophthalmologic methods. Mosquito forceps are known for their fine tips, and short, completely serrated jaws. They are accessible curved or straight. The standard length for this instrument is 5 inches, in spite of the fact that we offer some with a length of 5-1/2 inches on demand. Halsted Mosquito Forceps are fundamentally the same as Hartmann Mosquito Forceps, be that as it may, the Hartmann style is better and progressively delicate. This item is bent with serrated jaws, 1 X 2 atraumatic teeth and a length of 4-3/4" inches.

Key Features of Vascular Mosquito Forceps.

Surname: DeBakey Mosquito.

Length: 4-3/4" - 12cm

Tip Configuration: Blunt-Non-Atraumatic

Instrument Type: Hemostatic Forceps

Curvature: Curved & Straight

Jaws: 1x2 Rows of Atraumatic Fine Teeth

Handle: Finger Rings

Material : Stainless Steel

Sterile or Non-Sterile: Non-Sterile

Latex or Latex-Free: Latex-Free

Click the link To get more variety of "ATRAUMATIC FORCEPS", related also with cardiovascular surgery procedure.

- Sterilization: Surgical instruments may be steam autoclaved at a temperature of 121°C (250°F) for 30 minutes or flash autoclaved at a temperature of 127° to 132°C (260° to 270°F) for 10 minutes.

- Recommended Sterilization Parameters: PRE-VAC Unwrapped Goods Cycle 5 minutes at 132° C/270° F. Dry Time: none recommended.

Wrapped Goods Cycle 5 minutes @ 132° C/270° F Dry Time: 5‐20 minutes*

- Recommended Gravity. Unwrapped Goods Cycle 10 minutes @ 132° C/270° F Dry time: none recommended. Wrapped Goods Cycle 30 Minutes @ 132° C/270° F Dry Time: per facility recommendation. Wrapped Goods Cycle 60 Minutes @ 132° C/270° F Dry Time: per facility recommendation. *Depending on Hospital Protocol* Warning: Flash sterilization is not the recommended sterilization method. All surgical instruments and parts should be steam autoclaved when time permits. However, flash sterilization may be used when there is an immediate need for an instrument, injector, or accessory and there is no other alternative.

- Aeration: As required to return to room temperature or to start the next cycle.

- Contraindication: Hospital policy and procedure(s) take precedence over this protocol. Failure to use approved cleaning and sterilization procedures may void the warranty.

- Cleaning Instructions: Cleaning: All instruments must be cleaned to remove contaminated substances before sterilization. After each use, perform an initial cleaning within the sterile field by wiping the tool or instrument free of blood and body fluids. Then clean the instrument thoroughly with a mild soapy solution. Do not use alkaline-based cleaners. Complete preparation for sterilization by hospital procedure using an approved cleaning agent. Do not run any type of abrasive materials or steel brushes through the lumen of the tool. The abrasive material can score the inside of the tool, rendering them inefficient. After flushing, the instrument needs to be well-rinsed with warm to hot water. Visually inspect each instrument to ensure all fatty deposits are removed. All instruments should be cleaned and rinsed with mild, non-abrasive, grease-removing cleaners before they are sterilized. Gulmaher Instruments recommends that during the cleaning and rinsing procedures, all instruments should be inspected. Ultrasonic cleaning after manual cleaning is recommended.

Refund / Return Goods Policy

- Item must be in unused condition and the original packaging Or unopened. Sterilized, taped, modified, or abused items cannot be returned or refunded for credit.

- The customer is responsible for returning the item(s) to Gulmaher. Gumaher will issue merchandise return labels if the return is a result of Gulmaher's mishandling (shipping error, etc.).